… and then the equipment

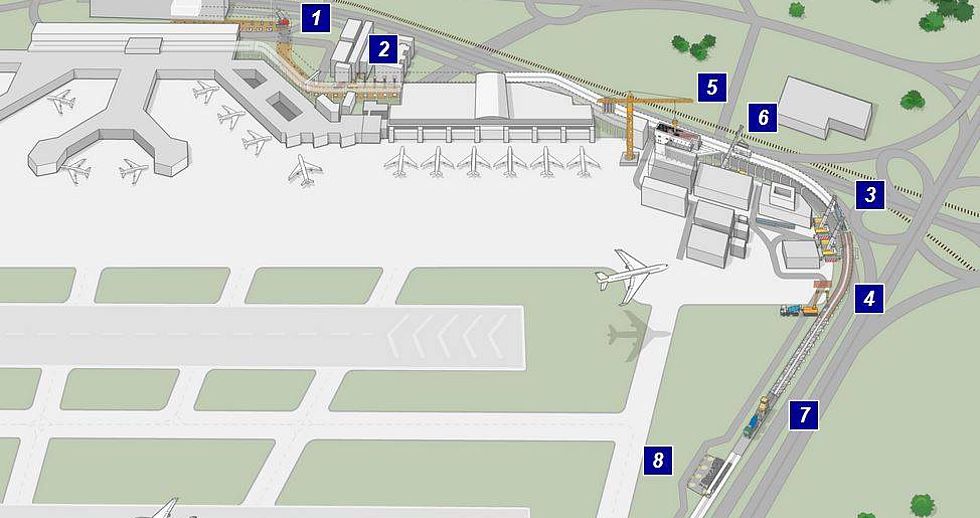

Once the carcass has been completed, work proceeded on the roof and interior. Everything was ready to go in the fall of 2022, when the first Sky Line vehicles were supplied and prepared for operation. A total of 12 vehicles will be delivered by the end of 2023. Each one is supplied in parts, which truck-mounted cranes lift onto the guideway near the maintenance facility. There engineers and mechanics take over and move them into the workshop for assembly and thorough testing. A lot of work still has to be done before they can start operating.